Unlocking Manufacturing Excellence with Data Insights

Aspect Productivity Technology, where we transform your manufacturing data into actionable insights, driving efficiency, quality, and profitability. Our flagship solution, Aspect, is designed to provide you with a comprehensive view of your manufacturing operations, enabling you to make informed decisions and achieve operational excellence.

Real-Time Production Data

Aspect offers visibility into your manufacturing processes. With real-time monitoring of machine status, production rates, and progress against schedules, you can swiftly adjust operations to keep production on track. Our downtime analysis feature provides deep insights into machine downtimes, helping you identify and address productivity barriers. Drill down to root cause analysis.

Quality Control

Maintain the highest standards of product quality with Aspect. Our system delivers detailed quality metrics, including pass/fail rates and defect types, allowing you to pinpoint areas for improvement. Compliance tracking ensures your manufacturing processes meet industry requirements, safeguarding your reputation and customer trust.

Maintenance and Machine Utilisation

Prevent unplanned downtime with predictive maintenance scheduling based on actual machine usage, driven by both machine and equipment uptime and cycles. Aspect’s insights into machine utilisation help you balance your equipment use with preventative maintenance, ensuring optimal performance and extending the lifespan of your assets.

Inventory and Materials Management

Achieve lean manufacturing with Aspect’s material usage tracking and work-in-progress (WIP) level insights. Our system enables you to adjust inventory levels based on production output in real time. Record scrap, and monitor production flow, with the aim of minimising bottlenecks and maximising efficiency.

Cost Analysis

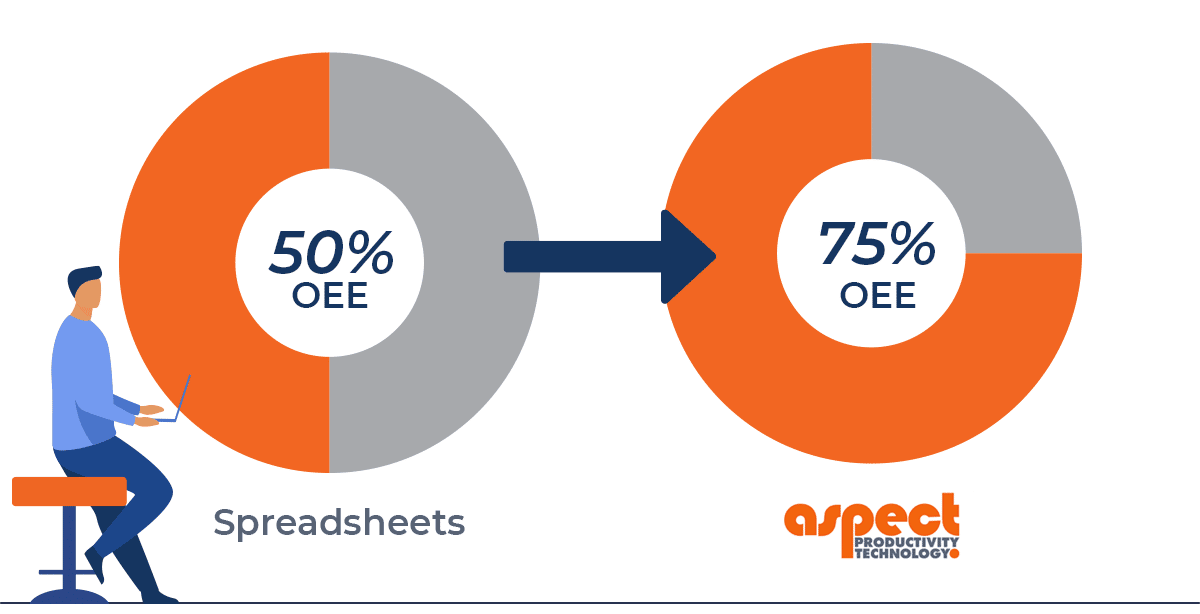

Aspect provides the data you need to identify cost reduction opportunities and conduct ROI analysis, demonstrating the financial benefits of implementing our system.

Maximise Productivity with Aspect

Contact UsCromford Pipe explain how AspectPL has streamlined machine maintenance and rapidly increased OEE and productivity

“Previously calculating OEE was a significant task – now with AspectPL it takes 20 seconds.”

Australian Blowmoulding uncovers hidden capacity

“It used to be hard to get a feeling for what was happening. Now if a customer rings, I can just look on AspectPL and see when the job will be done. They are amazed at how accurate I can be.”

Australian Blowmoulding

AspectPL MES manages high volume Pact Packaging Hamilton

“We are definitely seeing a return on investment in dollars, time and machine productivity.”

PACT Packaging Hamilton

Bonson Packaging – 2020 Case Study

“We reached a point where, if we wanted to grow further, we needed to embrace technology and digitise our factory environment. And the best technology we found is AspectPL.”

Bonson Packaging

Hansen Products Case Study

“The single most important thing is the transparency that AspectPL affords our manufacturing processes and team.”

Hansen

AspectPT interviews Steve Rush from Beckhoff Automation NZ

Having a Beckhoff PLC configured by AspectPT offers customers the confidence they are investing in MES software that is technologically advanced and able to grow with their business.

Beckhoff Automation NZ

Bonson Case Study 2016

With AspectPL gross utilisation of the manufacturing equipment increased from 70% to 95% and above, virtually eliminating unplanned downtime and manufacturing overruns on any of the machines

Bonson

Comprehensive Reporting

Aspect’s comprehensive reporting feature allows you to focus on the metrics most relevant to your operations, like – Material pick list, late orders, schedule, production, OEE, Maintenance etc.

Aspect provides instant access to a range of useful reports that allow you to make immediate operational decisions based on actual measured data, driving continuous improvement.

Transform Your Manufacturing Operations

With Aspect, you’re not just collecting data; you’re unlocking the potential of your manufacturing operations. Our solution empowers you to achieve greater agility, efficiency, and profitability, supporting a culture of operational excellence.

Discover how Aspect can transform your manufacturing data into actionable insights.

At Aspect Productivity Technology, we’re committed to helping you harness the power of your data to drive manufacturing excellence. Contact us today to learn more or to schedule a demo.